The carbon dioxide cycle

Carbon dioxide is at the forefront of all the media as soon as an extreme climatic disturbance appears since it is established that the essential cause is the continuous increase of the temperature of the Earth’s atmosphere which is incumbent upon it.

This negative observation must not hide, however, that without :

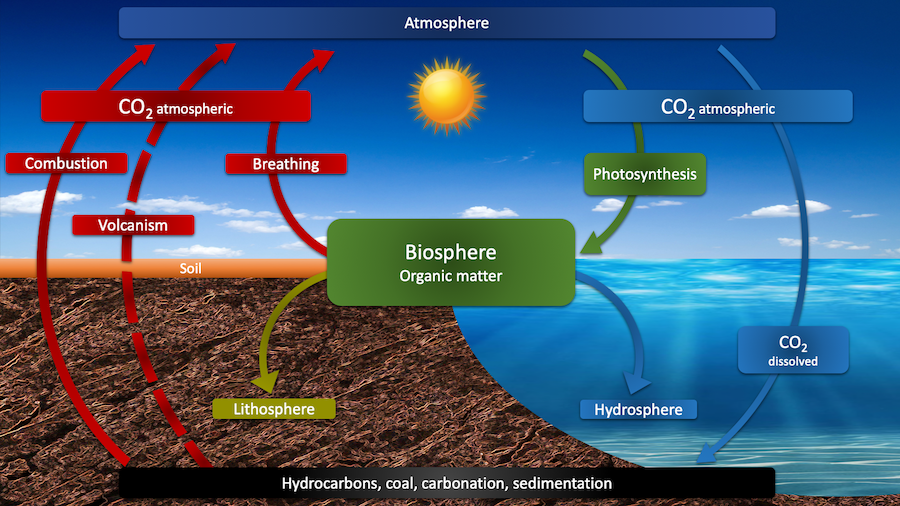

- its combination with water, catalysed by photosynthesis, there would be no animal, no biomass and no oxygen, so no life on earth,

- its ability to retain infra-red radiation therefore to be one of the major elements of the greenhouse effect without which the Earth would be too cold to be inhabited

In fact, carbon dioxide is perceived as a pollution only since the beginning of the industrial era. The cause is known to all: it is the massive consumption of coal and oil for raw materials and energy whose combustion massively rejects carbon dioxide of fossil origin in the atmosphere, increasing its concentration of 0.028% at the beginning of the 19th century to 0.035% in 1958, 0.038% in 2005, 0.040% in 2015.

These values do not represent all the carbon dioxide of fossil origin sent into the atmosphere since the oceanic hydrosphere will absorb a very large share by dissolution. The continental and oceanic lithospheres absorb a significant part of them by carbonation and sedimentation.

The following diagram summarizes this status :

The most visible consequence of this massive release of fossil carbon into the atmosphere was the increase of 1°C in the average temperature of the earth’s atmosphere with the consequences that we have known for the last decades.

If we want to stay within the limits of a temperature increase of 1.5°C recommended by the IPCC so that droughts, floods, food and migratory crises do not violate our society violently, we must leave coal and oil where they are.

For this it will simply remove the atmospheric combustion of fossil hydrocarbons. The statement may seem fanciful and provocative when you know the industrial importance of the sector but it is inevitable if we want climate change to take unbearable turns.

The world’s major banks are already beginning to anticipate it and see all the major oil companies progressively emancipate themselves gradually from the fossil resource that made their fortune to take over renewable resources with the means required to bring the planet out of existence. the perilous situation looming on the immediate horizon.

The LEEBIO™ process is going to be a decided actor of this great planetary upheaval since it uses biomass as an ideal concentrator of atmospheric CO2 by producing energy and raw materials for the industry in an endless cycle where the only energy involved is that of the sun.

So I took advantage of my freedom found since late June 2016 to study what my concept of plant refining could bring positive energy recovery of lignocellulosic biomass that doze in its principles and results and cannot show a semblance of profitability that by paying very badly the raw material, if possible with solid public subsidies.

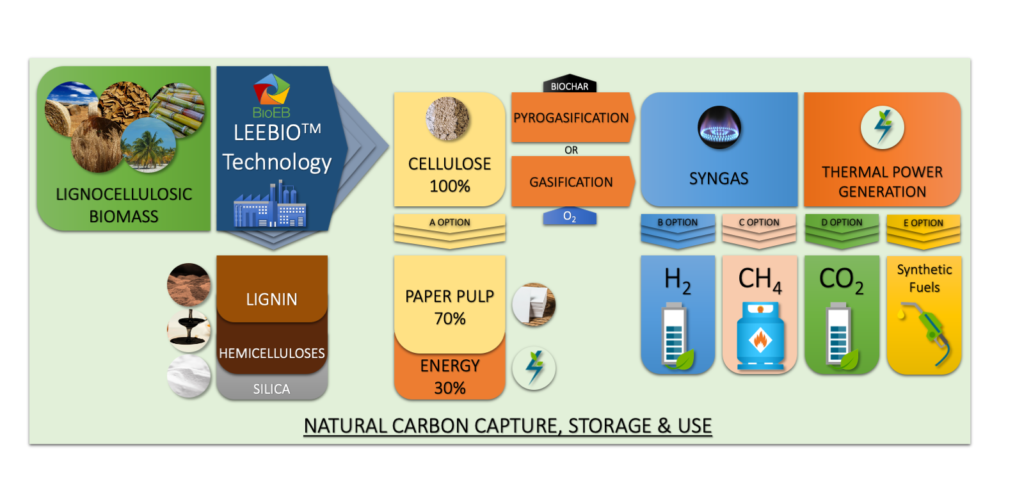

It must be known that lignin is considered by everyone as the high energy part of biomass. This is certainly true in apparent theory but, when we look a little closer, it appears very quickly that the many problems related to thermochemical conversion of biomass into combustion, liquefaction, pyrolysis, carbonization or gasification have as their main cause the lignin and its tendency to make tars.

On the other hand, cellulose does not have this disadvantage in gasification with a quantitative production of synthesis gas and therefore a remarkable energy balance.

This requires the refining process to be particularly energy efficient. This therefore implied lot of changes compared to the CIMV process. They came from an observation I made and published at the beginning of the 2000s, namely that the use of pure formic acid around 100°C to proceed with the destructuration of the straw remained effective but with proportion of significant furfural that led me at this time to prefer and develop the mixture acetic acid / formic acid that made the CIMV process and its remarkable performance that we have just seen.

In fact, to change the paradigm again and significantly improve the energy balance, it was simply necessary to lower the temperature around 80-85°C.

The consequence was the disappearance of the furfural mortgage without significantly altering the separation process and the quality of the products obtained as we will see.

The acronym for the process: LEEBIOTM, under which it will be developed is built on : Low Energy Extraction of Biomolecules which translates into English the first characteristic of this process which is to be at the moment, at the same time the most energy efficient while by remaining extremely efficient on the quality of the products extracted and / or processed.

So, I created, to develop this brand new concept BioEBTM, a contraction of Biomass, Energy, Biomolecules which is operational since July 1st 2018 and will be in charge of the implementation of the technology.

This particularly energetic refining is very efficient in the following schematic conditions for three different raw materials, representative of lignocellulose in general: sugarcane bagasse, rice straw and birch :

On the basis of what can be estimated from the industrial and commercial data accumulated over the years, a minimum price of 100€/T for the dry raw material can easily be paid to the producer with regard to the estimated minimum valuation transformation products around 600€/T of incoming raw material.

The operational simplicity of the technology and its reduced energy consumption therefore allows a remarkable profitability, even for small units.

Moreover, and today it is a point of primary importance not counted in the above estimate: The technology is generating for all its production of carbon credits which are today decisive elements in the making of decision of any organic matter transformation project.

It is worth remembering that carbon credits are units that are allocated to any project that reduces greenhouse gas emissions. A carbon credit represents a reduction of one ton of CO2.

For example, a BioEB plant that avoids the emission of XT from eqCO2 per year because it avoids burning coal, oil or gas in a thermal power plant to produce the same amount of electrical power or industrial products will be allocate X carbon credits each representing 1 ton of eqCO2 avoided. It will sell its carbon credits to an entity that must offset its produch tion of fossil CO2 at market price. The income will come in addition to the previous estimate.

The Institute for Climate Economics, founded by the French state bank: Caisse des Dépots, provides an excellent vision of what will be the carbon credit in the very near future and its more than positive effect for my concept of vegetable refining in the broad sense. https://www.i4ce.org/

BioEB will of course work very closely with a large global network of companies, research centers and universities that I have built over the years.

The Syngas derived exclusively from cellulose can therefore be transformed in many ways that will have no influence on the greenhouse effect because they do not at any time use fossil fuels.

In a first option, Syngas can be converted into kerosene and other biofuels by the well-known Fisher and Trops reaction. The image of the aircraft that takes its fuel in the air from atmospheric carbon dioxide is not a utopia but could be an effective reality at short deadline with the LEEBIO ™ process because the technologies used are already developed at industrial scale.

The second option involves the combustion of Syngas to produce electrical energy and pure carbon dioxide at high concentrations.

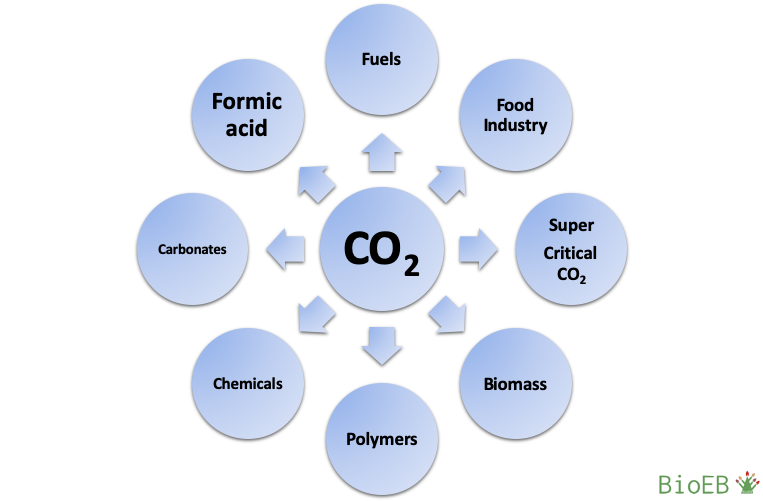

In this case, potential industrial developments on this carbon dioxide of atmospheric origin are not lacking with a chain of transformation resembling petrochemistry :

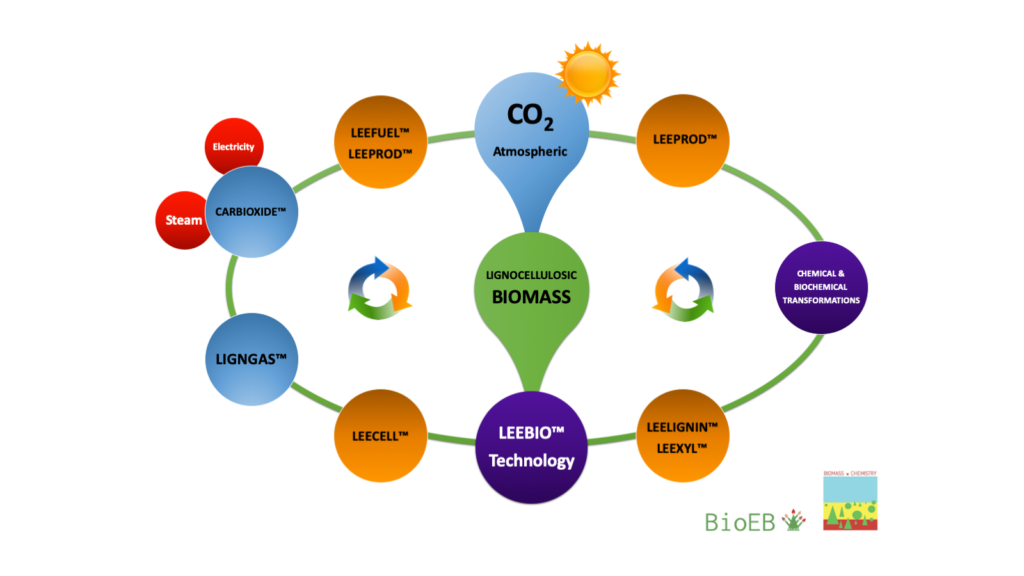

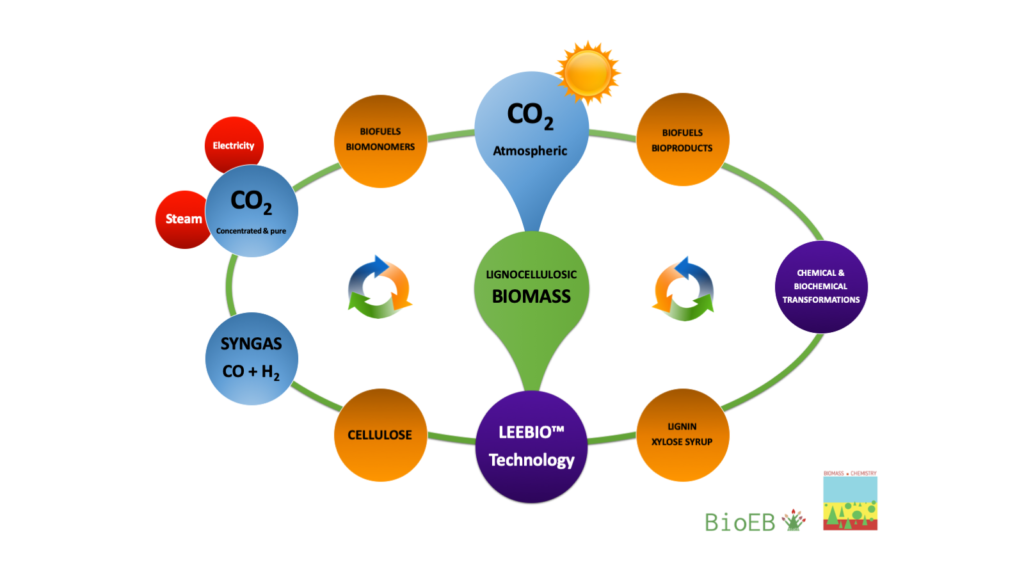

The following two cycles summarize the new CO2 raw material cycle, to which we have brought its green dimension with the different commercial brands generated by the LEEBIOTM technology, which gives it exceptional profitability.

From then on, big oil and chemical companies will take charge of their development.

Patents

They are systematically referenced on the basis of their European registration number to facilitate their access. They have all, without exception, been extended or are being expanded in all the major countries of the world.